Generate Smarter Insights

built on the Integrity of LYTT

LYTT’s industrial AI sensor platform is compatible with high-fidelity sensors, and capable of collecting and analyzing petabytes of data from machinery and processes, in real time. Our advanced algorithms convert the data into actionable insights, giving a better understanding of operations to make more accurate, data-driven decisions.

- Intelligent feature extraction

- Sensor fusion analytics

- Operational insights – 24/7

- AI ML development framework

- Pattern recognition framework

- Extract value from large amounts of data

- Specializing in high fidelity sensors

- Self-learning AI

Accelerate Operational Value

at the speed of LYTT

LYTT’s industrially proven AI platform has a scalable, open architecture that enables rapid development and deployment of models, enabling the creation of your own, branded, solutions. Empower data scientists and non-experts to accelerate development of value generating solutions. Take advantage of access to LYTT’s extensive library of industry proven solutions to realize instant business impact.

- Fit for purpose

- Shorten the development cycle

- Leveraging industry tested and proven solutions

- Fast deployment

- Seamless cloud integration

- Dynamically respond to new challenges

- Built on an open architecture

- Scalable

Monetize Sensor

Data

shed new LYTT on your Data

Monetizing sensor data becomes easier and realistically achievable with the LYTT Industrial AI platform, by seamlessly connecting real-time insights to operational decisions, digital-twins, and automation. Maximize IIOT sensor investment by utilizing sensor data to drive preventive maintenance, process optimization and prediction workflows that deliver real business value.

- Monetize and maximize your investment

- Increased operational excellence at reduced cost

- Value from historic sensor data

- Leverage your existing insights models

- Connected insights to all your data

- Not just anomaly detection

- Industrially proven value, delivered

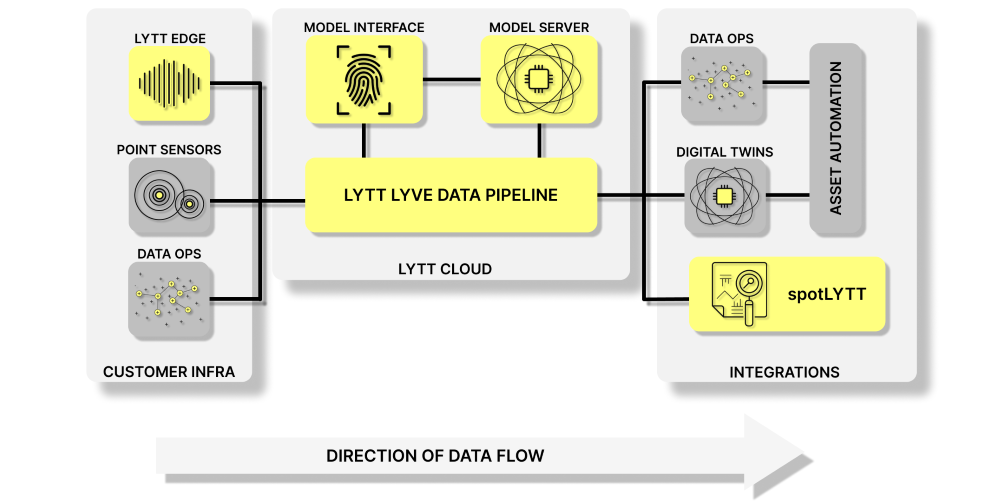

PLATFORM OVERVIEW

PLATFORM FEATURES

Platform Core

Central to LYTT’s standard platform offering, our platform core: stores historical and real-time data collected from IoT devices and high-fidelity sensors, integrates data from 3rd-party and EDGE data sources and allows users to search, retrieve, and visualise data sets. Our platform core also integrates with LYTT sensor fusion and model deployment features is highly scalable to meet changing demands, and resilient, which ensures high availability. Deploy across multiple clouds and on-prem.

Sensor fusion analytics

Combine data from multiple sensors and sources to provide a more accurate and complete understanding of your systems and processes. Utilize sensor fusion to enable highly accurate and reliable model predictions and unlock more powerful insights.

Third-party model deployment

LYTT’s platform allows customers to deploy their existing, pre-trained models on top of the Platform Core. Realize cost savings and decrease time to market by utilizing the LYTT Platform’s existing model deployment capabilities.

Third-party model development

Complete the data science life cycle on top of the LYTT’s AI platform. Access training data, build and deploy models within LYTT’s integrated data science environment. The fastest way to move from initial data exploration to deploying production-ready models with actionable insights for high-fidelity sensors.

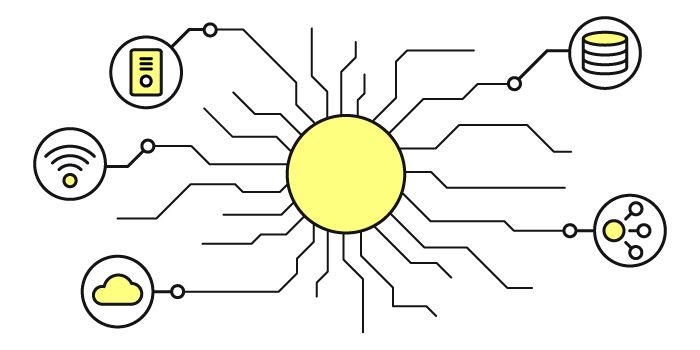

Third-party software integration

Enables users to extract more value from their IoT data by integrating software applications or services developed by third-party vendors into LYTT’s AI platform. This includes applications and services related to data analysis, visualization, digital twins, and asset automation.

spotLYTT™ visualization

spotLYTT™ is LYTT Platform’s bespoke user-friendly data visualization dashboard. It takes the data gathered by our patented, field-proven analytics tools and turns it into contextualized insights via a single, intuitive dashboard. It gives you the freedom to visualize and analyze relevant data in real-time for faster, more informed decision making.

PLATFORM COMPONENTS

LYTT EDGE

LYTT’s edge computing solution intelligently extracts the key features from sources like distributed acoustic sensing (DAS) and distributed temperature sensing (DTS) data streams within seconds, reducing the volume of data by 1,000 times – without compromising quality

Self-learning models

Improve model accuracy and strengthen performance with continual learning. Automatically feed manually labelled data back into your machine learning pipeline to retrain models and improve predictive accuracy.

Connector library

Choose from a range of pre-built connectors to quickly and easily connect IoT applications and devices with LYTT’s AI platform. Integrate with a wide range of external software systems for data analysis and visualization. Feed data and insights from the platform into digital twins and asset automation systems.

LYTT Platform data pipelines

Real-time processing engine. Respond to events in real-time. Route sensors from multiple different sources to the appropriate models.

PAPERS

As thought leaders, LYTT has published numerous papers highlighting our subject matter expertise and demonstrating our innovative and proven technology in action.

FIBER OPTIC COMPANION TECHNOLOGIES

Distributed acoustic sensing

Distributed acoustic sensing (DAS) technology essentially turns a fiber optic cable into a long microphone, making it possible to track different sounds, such as oil, gas or sand moving in a well from the reservoir all the way to the surface.

However, DAS produces an extraordinary amount of data. For example, a single hydrocarbon well can generate 100 million data points every second. That’s like streaming 1,000 full movies every hour. Until now, it has been difficult for operators to convert this data into useful insights in a timely manner. But our data analytics solutions are changing all that.

Distributed temperature sensing

Distributed temperature sensing (DTS) uses fiber optic cable to continuously record temperature. DTS is particularly useful in certain operational environments where temperature can affect operational decisions.

DTS has proven challenging to operators, as it has traditionally taken them a long time to interpret. Our data analytics tools and solutions make light work of this, collecting, processing and analysing DTS in real time.